- (+91) 9975801764

- info@perfectengineeringindia.in

- An ISO 9001 - 2015 & MSME Certified Company

Air Blower Manufacturers/Suppliers/Exporters in India

Perfectplus Engineering India Pvt. Ltd. is a leading manufacturers, suppliers, and exporters of air blowers in India. Our products are available in a wide range of variety to suit any need and budget. We air blower manufacturers, suppliers, and exporters in India have a team of experienced engineers and designers who can provide you with the latest designs as per your needs.

The air blower in India offers quality products that are made with high-quality standards and the latest designs that are designed to meet the needs of different industries. We offer a wide range of variety in their product line and provide an expert team for installation, service, and after-sale support.

The air blower in India is known for the standard quality products that are designed with the latest technology and best engineering practices.

What does Air Blower mean?

An air blower is a device that uses compressed air to blow the dust and debris away. It creates a vacuum to remove dust and debris from the air. It is useful for cleaning and maintaining the health of your home. These units can be found in different shapes and sizes depending on the size of the room they will be used in.

Air blowers come in two main types, one that is fixed and another that is portable. The fixed type of air blower has a motor which is attached to an external power source, while the portable type uses an internal battery to power its motor.

Air blowers are typically made up of a motor and fan blades, which are attached to an air hose with a nozzle at one end and an exhaust valve at the other. The motor is connected to the power grid via an electric cord or AC power adapter and is controlled by a thermostat or timer.

Features of Air Blower:

- It comes with a small electric motor that runs on batteries.

- The air that it blows into the lungs can be regulated by adjusting the pressure settings.

- It has an operating range from 0 to 300 psi and can be used for both children and adults.

- They are also very helpful in removing dust and debris from the area they are being used.

- It has the ability to be able to adjust the speed of the fan, power levels, and the size of the fan.

Air blowers are used in the construction industry to blow away dust and debris. They are also used in other industries like manufacturing, textile, and mining. These blowers are used in many different places such as offices, homes, and cars.

Centrifugal Blowers, are used for numerous industrial applications including: aeration, air bars/formers, air bearings, air conveying, air injection, air knives, air scrubbers, air tables, combustion air, cooling, environmental test chambers, exhaust emission testing, flow benches, fluidized beds, gas boosting, gas exhausting, inflation air, vacuum collection, vacuum hold-down and vacuum pick-up.

| Blower Type | centrifugal blower fan |

| Power | 1 HP - 60 HP |

| Phase | 3 Phase |

| Model Name/Number | Perfectplus Engineering India Pvt. Ltd. |

| Usage/Application | Industrial |

| Material | MS/CS/SS304/SS316 |

| Pressure | Medium Pressure, High Pressure, Low Pressure |

| Power Source | Electric Blower |

DEGASSER AIR BLOWER

Degasser Blower are suitable for the exhaust of clean air, lightly dusty.

Low, medium and high pressure simple and double inlet, models with various volume flow for the different necessities.

Backward impellers at high efficiency with flat, wing and Sirocco profile.

Indicated for the various application of the ventilation, air-conditioning and processes industry.

MB AIR BLOWER

ETP/STP/MB/PSF Air Blower

| Motor Rating | >12 HP |

| Brand | Perfectplus Engineering India Pvt. Ltd. |

| Material | Cast Iron |

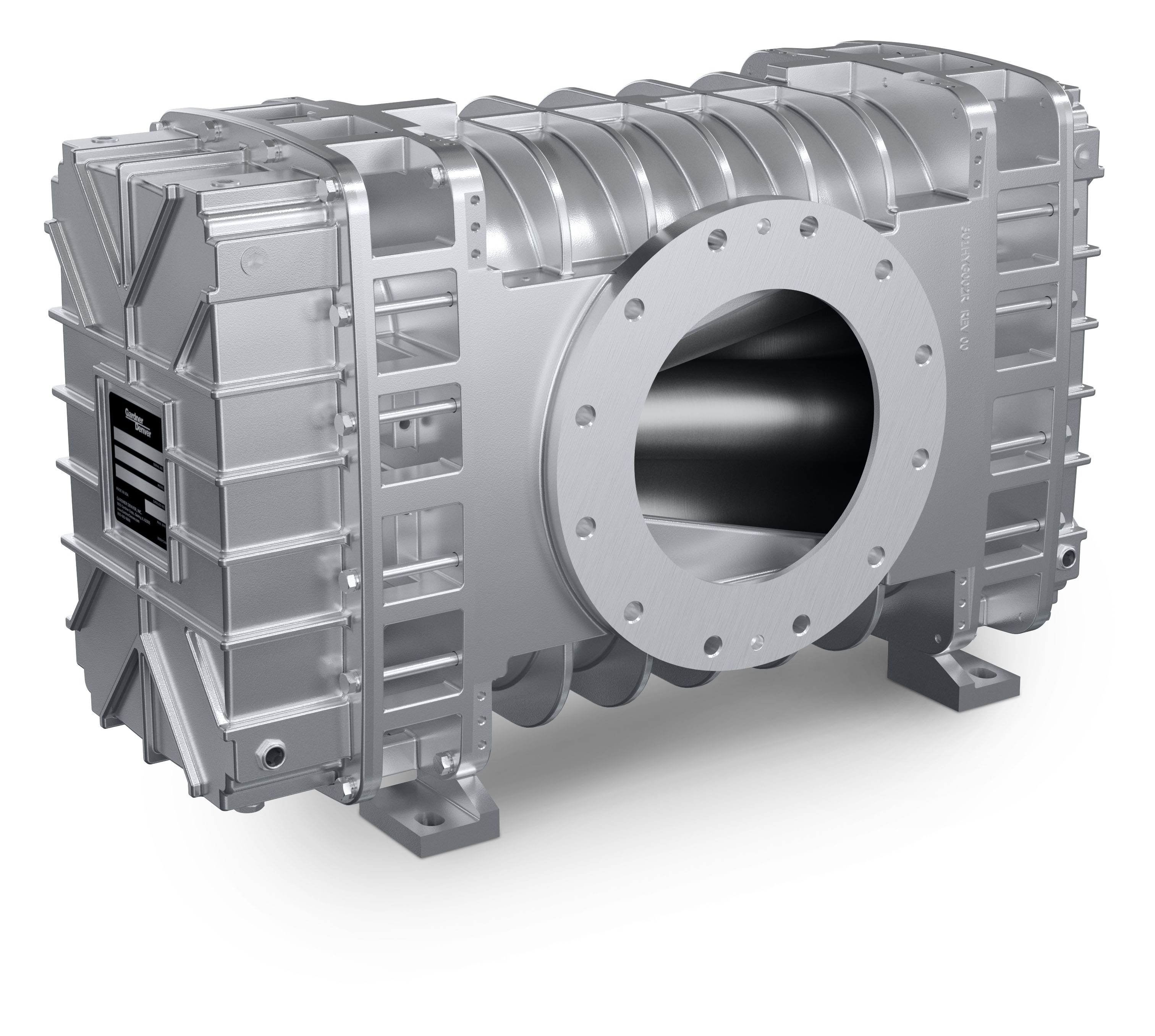

ROTARY BLOWERS

A rotary lobe blower is a type of positive displacement blower that utilizes two parallel rotary pistons mounted within a housing that rotate in opposite directions. The pumped medium is sealed in the space between the rotors and housing. It is compressed, pumped through the housing to the gas discharge by the rotary motion and discharged.

A silencer with integrated inlet filter is connected upstream of the blower stage. Once the medium has been compressed during the blower stage, it flows through the downstream discharge silencer. The drive unit is operated with a motor using a v-belt. The v-belt drive enables the blower speed to be precisely adjusted to the process requirements.