- (+91) 9975801764

- info@perfectengineeringindia.in

- An ISO 9001 - 2015 & MSME Certified Company

Pressure Vessels/Tanks Manufacturers, Suppliers, Exporters in Pune

Perfectplus Engineering India Pvt. Ltd. is a leading Pressure Vessel/Tanks manufacturers, suppliers, exporters in Pune, providing a wide range of valves for industries like water treatment, chemicals, power generation and oil and gas. We Pressure Vessel/Tanks manufacturers, suppliers, and exporters in Pune have been in the business of manufacturing and supplying high quality valves for more than 8 years.

The pressure vessels/Tanks in Pune have a team of experts that have been offering services in the field for the last seven decades. We Pressure Vessel/Tanks manufacturers, suppliers, and exporters in Pune of the most trusted engineering companies in Pune. We provide the best quality products that are cost-effective and reliable.

The pressure vessels/tanks also offer a wide range of valves from standard to latest designs. With an expert team that includes experienced engineers and designers, they can offer high-quality solutions for any industry or project.

Introduction-

Pressure Tanks are used to create pressure in a liquid or gas. They can be used to regulate the pressure of liquids or gases, and they are usually made up of a vacuum flask, an airtight lid, and a delivery tube. They are usually made from a metal or plastic and have a valve on the top that releases pressure when it gets too high.

Pressure Vessels are designed to withstand high pressures or extreme temperatures. They can be made of steel, aluminum, titanium alloy, or carbon fiber. The pressure vessels have the ability to withstand high temperatures and pressures without damage.

Features:

Pressure vessels and tanks are designed to be safe, durable, and reliable. These tanks also have airtight seals that make it difficult for water or other liquids to leak into them.

The features of Pressure Tanks/Vessels include:

- Built-in sensors that measure pressure and temperature,

- Pressure relief valves that allow air to escape when it gets too high,

- A built-in pump that circulates liquid through the tank,

- A built-in heater or cooling system for temperature control.

- Pressure relief valves that allow for quick release of pressure in case something goes wrong

- Filtration systems that remove sediment from the water before it is stored

Benefits of using Pressure Vessels/Tanks-

Pressure Tanks/Vessels are available in different shapes and sizes to suit your needs. They come with pressure gauges to measure the pressure of the air inside them; they also come with a variety of air filters to ensure that they are safe for use.

They can be found in laboratories, offices, warehouses, and on the street corners. They also help keep liquids from evaporating too quickly by providing an airtight seal around them.

Applications:

Pressure tanks can be found in many industries, such as oil and gas, petrochemical, and mining. chemical, pharmaceuticals, and food processing.

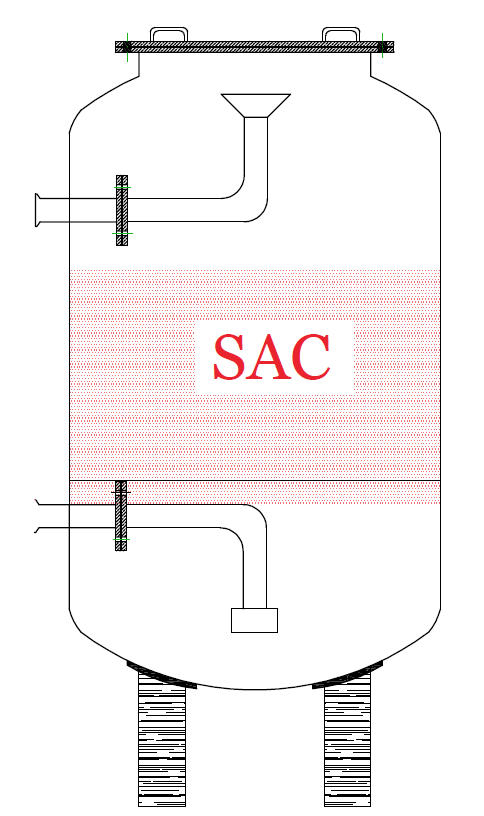

Strong Base Anion Vessel

Strong base anion unit is a vessel in which an ion exchange process takes place. OH¯ ions replace the anions present in TDS to produce demineralized water. The anions present in the water i.e. Cl, SO4, HCO3 and silica etc. are exchanged with OH¯ ions available in the resin and water is demineralized. Therefore, water becomes demineralized resulting in a solution of pure water. When the anion exchanger gets exhausted, it is regenerated with caustic solution to replenish OH¯ ions. They can be operated manually or automatically. They are available as co-flow and countercurrent regeneration units.

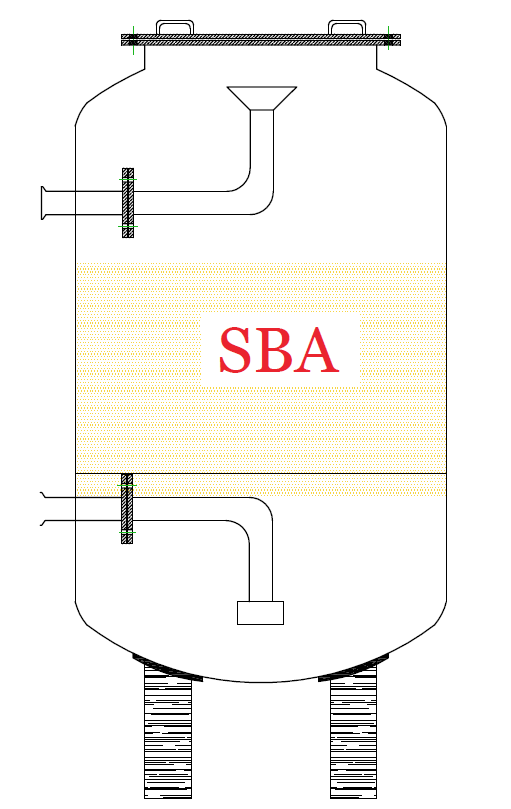

Mixed Bed Vessel

Mixed bed is used to remove traces of ion in water. Basically it is used after DM/RO plant depending on TDS

| Brand | DURASHELL |

| Capacity | 100-500 L |

| Material | FRP |

| Features | Vertical Orientation |

| Max Design Pressure | 0-10 bar |

| Vessel Dimensions ( length X width X Height) | 844-3072 |

| Minimum Order Quantity | 1 Unit |

Softner Vessel

| Capacity | 10000 L |

| Softener Tank Type | Vertical |

| Material | Mild Steel |

| Capacity (m3/hr) | 3.0, 50 |

| Max Design Pressure | 0-10 bar, 10-15 bar, 15-20 bar |

| Body Material | Stainless Steel |

| Type | Softener, Water Softener |

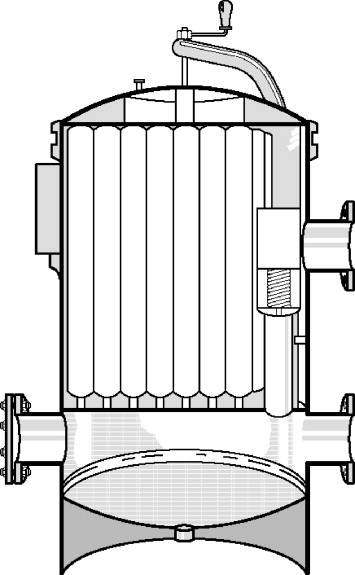

Pressure Sand Filter

These filters are the most popular method for removal of turbidity from water. The Pressure Sand Filter consists of a multiple layer of sand with a variety in size and specific gravity. These Filters are designed to remove turbidity and suspended particles present in the feed water with minimum pressure drop. These Filters are custom designed to suit the process requirement. These filters are offered in Mild Steel, FRP or SS construction with face piping and associated Valves.

Activated Carbon Filter

Activated carbon filters are small pieces of carbon, typically in granular or powdered block form, that have been treated to be extremely porous. It is so cavernous, in fact, that just one gram of activated carbon can easily have a surface area of 500m2 or higher. Vast surface area enables these carbon filters to adsorb exponentially more contaminants and allergens than traditional carbon.

Multi Grade Filter

The MGF works on principle of retention and removal of physical impurity in a graded manner through Voids of the filtering media.

Multi grade filter is a depth filter that makes use of coarse and fine media mixed together in a fixed proportion. This arrangement produces a filter bed with adequate pore dimensions for retaining both large and small suspended particles. This filter performs at a substantially higher specific flow rate than conventional filters.

Cartridge Filter

Solid material suspended in the water gets trapped on the cartridge

filter. The filter will be rated to remove particles of a certain size – for

many supplies, several filters in descending order of particle removal size

will be needed. A typical choice would be a 20 micron filter followed by

a 5 and / or 1 micron filter, but the exact choice depends on the quality of the supply and the

substance(s) that need to be removed. The filter should be clearly marked with its size rating.

As long as they are installed and used correctly, cartridge filters can remove

sediment, metals and some microorganisms from the water. It is necessary to

make sure that the filters are correctly sized for the flow of water you require,

otherwise they may block. Cartridge filters work best in situations where there is

not much solid material in the water supply and little iron or manganese (less than

about 300 microgrammes per litre) of iron. Filters containing loose media may

need to be used where there is a significant quantity of sediment in the water or

higher concentrations of iron and manganese. In order to remove Clostridium with

certainty, a filter rated at 0.5 micron will be needed. For Cryptosporidium this

should be 1 micron. Some filters are impregnated with carbon to remove low

concentrations of the organic compounds that cause colour in water.

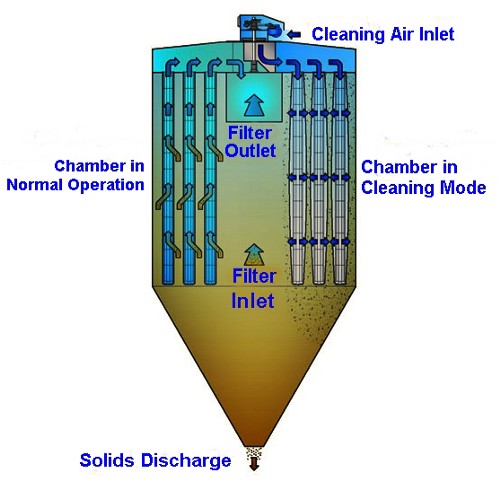

Bag Filter

A Bag Filter is an air pollution controlling industrial equipment, used prominently in a Steam Boiler House Assembly. It is used to control the levels of sulfur dioxide and others. There are different types of Bag Filters such as Shakers, Reverse Air and Pulse Jet type, with Pulse jet type being the most promising one of outstanding results.

Acid Measuring Tank

With our years of experience, we are engaged in manufacturing an exclusive range of Acid Measuring Tanks to our valued clients. These tanks are sturdily designed and ensure long lasting service life. The tanks that are offered by us are available in different capacities and dimensions.

| Max Pressure | 100-150 psi |

| Storage Capacity | 250-500 L |

| Storage Type | Any |

| Warranty | Any |

| Wall Thickness | Any |

| Usage/Application | Any |

| Capacity | 5000-10000 L |

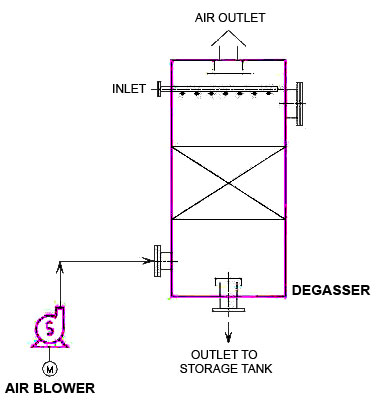

Degassed Tower

Degasser in water treatment is referred to Decarbonator where the primary importance is to remove Carbon Dioxide from the water. They play an important role when Alkalinity is present in water. Water containing alkalinity causes deposits and blocks the tubes in the boiler. It is placed after the Cation exchanger to mechanically remove the Carbon Dioxide. Water containing Bicarbonates when passed through the Cation Exchanger is converted to Carbonic Acid. The Carbonic Acid easily breaks into Water and Carbon Dioxide. HCO3 = H2O + CO2 This CO2 can be mechanically removed by the Degasser by blowing air counter current to the water flow.

Bulk Acid Storage Tank

Bulk Acid Storage Tanks: Other Details:

Supplied with fire retardant and ultra violet resistant additives as per specific requirements.

Suitable for using highly corrosive chemicals at maximum temperature up to 150 degree centigrade.

Designed for pressure and vacuum conditions.

Supplied with double wall construction.

Designed and supplied for above and underground applications.

Thermoplastic welded joints with conductive layer.

Vertical cylindrical, horizontal cylindrical and with require type of end closures.

Supplied along with additional accessories like ladder, handrail, platform, level indicators, leg supports and saddle supports.

Advantages:

Very good corrosion resistance

High mechanical strength at low specific gravity

Good resistance to weathering

Light weight

Good insulating qualities

Provide less maintenance repairs down time

Easy installation

Capacity:

up to 100 KL

| Storage Material | Water, Chemicals/Oils, Milk/Dairy, Gases, Waste |

| Capacity | 0-250 L, 250-500 L, 500-1000 L, 1000-5000 L, 5000-10000 L |

| Features | Leg Support, Horizontal Orientation, Vertical Orientation, Level Indicator Equipped, High Temperature Resistant |